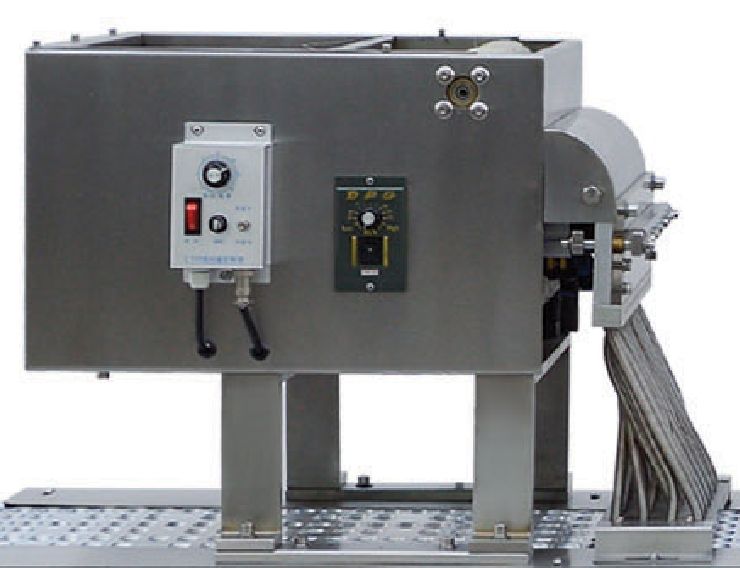

Maganin Kunshin Ƙarƙashin Magunguna Don Allunan da Capsules

Siffofin

1. Za'a iya raba na'urar gaba ɗaya zuwa marufi don shigar da lif na mita 2.2 da tsaga tsafta.

2. Maɓallin maɓalli duk an yi su ne daga bakin karfe mai inganci da kayan haɗin gwal na aluminum.

3. Novel mold sakawa na'urar, Yana da matukar dace don maye gurbin mold tare da sakawa mold da dukan jagora dogo, saduwa da janar bukatun na sauri mold canji.

4. Domin mai zaman kanta tasha yi indentation da batch lamba rabuwa, don tabbatar da tsabta na indentation da bugu (indentation da batch lambar kuma iya zama a cikin wani matsayi).

5. An ware watsawar na'ura daga wurin aiki don hana gurbatawa da sauƙaƙe tsaftacewa.

6. Abincin kayan abinci yana sarrafawa ta hanyar daidaitaccen motar servo, daidaitaccen daidaitaccen aiki da tsawon bugun bugun jini an saita shi ta hanyar injin injin.

7. Ana sanya silinda mai ɗaukar zafi a ƙarƙashin tashar tashar zafi don rage cibiyar injin, haɓaka kwanciyar hankali na kayan aiki.Don yankin da tsarin watsawa ya keɓe gabaɗaya don hana gurbatawa, mai sauƙin tsaftacewa.

8. Aluminum / filastik (zafi forming) da aluminum / aluminum (sanyi forming) General Cibiyoyin: Aluminum / Aluminum shiryawa kawai canza mold da m feeder ne OK.

Aikace-aikace

Babban halayen wannan kayan aiki yana amfani da ƙirar ƙirar ƙira, dacewa ga abokan ciniki don maye gurbin mold, rage lokacin lalatawa da farashin kayan abu, mahimman sassa ana yin su ne da ƙarancin ƙarfe da ƙarancin ƙarfe na ƙarfe na ƙarfe mai ƙarfi ta hanyar machining cibiyar (CNC), yankan layin madubi da sauran manyan madaidaicin CNC kayan aiki a cikin nau'in sarrafawa ɗaya, riƙe da ainihin rubutun karewa, haskaka darajar daraja. Madaidaicin murfin kariya na kyakkyawan aiki na baka don tabbatar da aminci da sarrafa zanen aikin murfin bakin karfe yana ƙara salo mara iyaka don ƙirar gabaɗaya, samfuran injin kuma na iya haɓaka fara'a na fasaha, duk aiwatar da cikakkun bayanai game da neman cikakkiyar ra'ayi a cikin ƙira da samarwa.

Ƙayyadaddun bayanai

| Samfura | DPP88 | Saukewa: DPP140 | Saukewa: DPP250 | Saukewa: DPP350 | |

| Mitar Yanke (yanke/minti) (masu girma dabam: 80*57mm) | 10-30 | 15-45 | 15-45 | 15-45 | |

| Max. Wurin Ƙirƙira da Zurfin (mm) | 100*90*15 | 140*110*15 | 250*120*15 | 350*130*15 | |

| Daidaitacce Iyalin Tafiya (mm) | 40-100 | 30-120 | 30-130 | 30-140 | |

| Kayan tattarawa (IDΦ75) | PVC (mm) | (0.15-0.4)*110*(Φ300) | (0.15-0.4)×160×(Φ350) | (0.15-0.4)×260×(Φ400) | (0.15-0.6)×350×(Φ400) |

| PTP(mm) | (0.02-0.15)*110*(Φ250) | (0.02-0.15)×160×(Φ350) | (0.02-0.15)×260×(Φ400) | (0.02-0.15)×350×(Φ400) | |

| Wutar lantarki | 220V/1P 50Hz | 380V/3P 50Hz | 380V/3P 50Hz | 380V/3P 50Hz | |

| Ƙarfi (kw) | 4.5 | 5.5 | 8 | 9.5 | |

| Matsawar iska (Shirya da kansa) | 0.6-0.8Mpa ³0.3m3/min | 0.6-0.8Mpa≥0.4m³/min | 0.6-0.8Mpa≥0.45m³/min | 0.6-0.8Mpa≥0.6m³/min | |

| Maimaita ruwa ko amfani da ruwa mai yawo (L/h) | 30-50 | 40-80 | 40-80 | 60-100 | |

| Gabaɗaya Girma (L*W*H)(mm) | 1700*450*1100 | 2400*650*1450 | 2900*750*1600 | 3650*850*1700 | |

| Nauyi (kg) | 300 | 800 | 1200 | 2000 | |

Rukunin samfuran

Jaridarmu ta mako-mako

Gaskiya ce mai tsayi cewa mai ja zai gamsu da shi

mai karanta shafi lokacin dubawa.

-

Imel

-

Waya

-

Whatsapp

-

Sama